News

Housing

According to the internal production diversification program, Uz-Koram Ko LLC plans starting production of 8 types of new products for consumer goods from EPP material starting from September 2016. All products planned for production are ecological clean products. These products can be classified as "Everything for the Home". Below you can read in detail all types of products

Name: "THERMO BOX"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Excellent insulation (from – 40 ° to +120° С )

- Ideal for hot, cold and fresh food

- Hygienic and ecological clean

- Very tightly closed with lid

Characteristics:

- Length 380 mm

- Width 285 mm

- Высота 355 мм

- Volume of 18 liters

- Weight 930 grams

Name : "Ironing board"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Ideal for use anywhere in the room

- Hygienic and environmentally friendly

- With a sheath

Characteristics:

|

Characteristics:

|

Name: "Carpet with a hole"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Ideal for toilets and sinks

- Hygienic and environmentally friendly

Characteristics:

- Length 714 mm

- Width 480 mm

- Height 50 mm

- Weight 416 grams

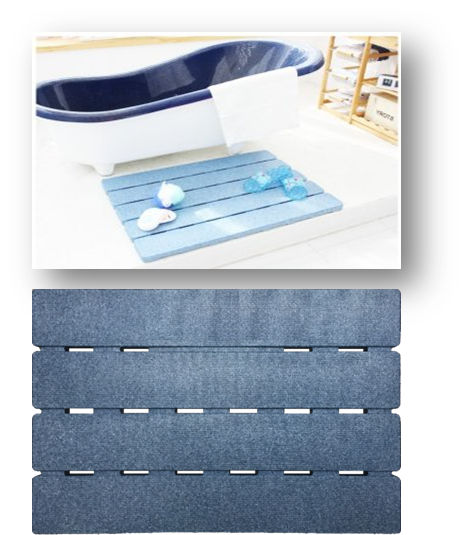

Name: "Carpet without hole"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Ideal for bathroom and living room

- Hygienic and environmentally friendly

Characteristics:

- Length 714 mm

- Ширина 480 мм

- Height 50 mm

- Weight 435 grams

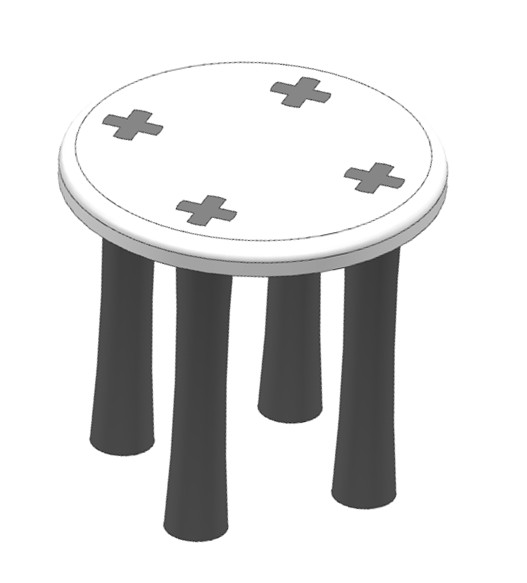

Name: "Children's chair"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Specially designed for children without risk of injury

- Separate removable legs, can be easily dismantled

- Hygienic and environmentally friendly

Characteristics:

- Diameter 650 mm

- Height 540 mm

- Weight 1200 gr

Name: "Highchair"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Specially designed for children without risk of injury

- You can easily stack on each other

- Hygienic and environmentally friendly

Characteristics:

- Diameter 310 mm

- Height 310 mm

- Weight 610 g

Name: "Universal high chair"

- Made from EPP (foaming polypropylene)

- Durable and lightweight

- Can be used as a chair with a backrest and for gaming purposes for children

- Hygienic and environmentally clean

Characteristics:

- Height from floor to back 600 mm

- Height from floor to chair 340 mm

- Length 360 mm

- Width 300 mm

- Weight 650 grams

Project for the development of components for a new model

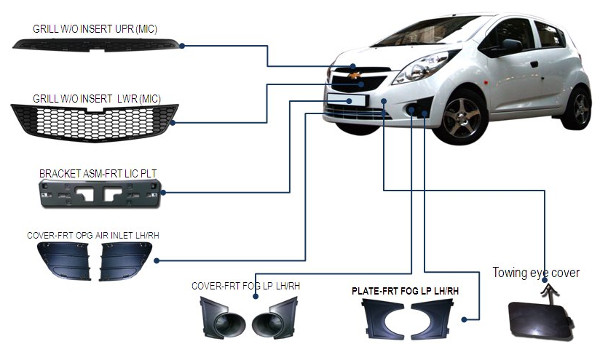

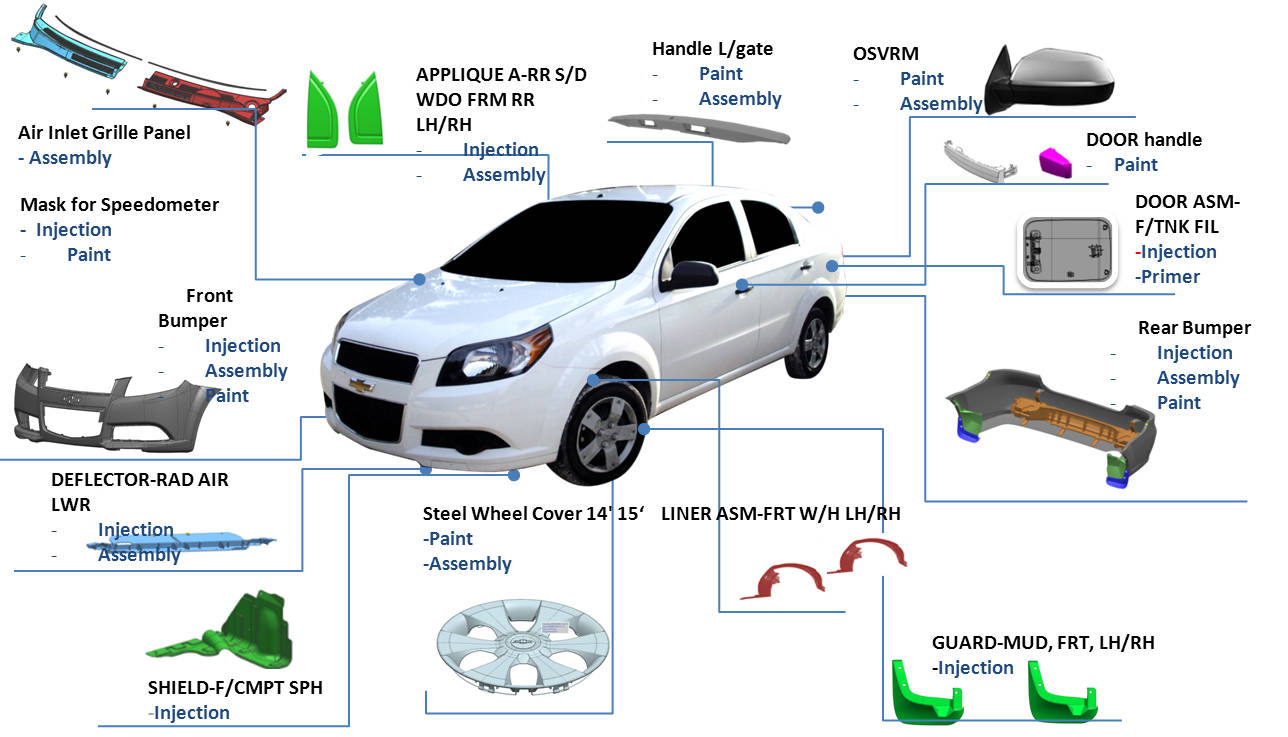

Within the framework of the program for mastering the new global model of JSC GM Uzbekistan, the company Uz-Koram Ko successfully completed the development of component parts for the new model of GM Uzbekistan JSC T-250 (Nexia-R3). The process of development lasted more than 1.5 years and from May 26, 2016 the project was successfully launched into mass production. According to the development program for this project, "Uz-Coram Co." has mastered 47 products that cover the processes of casting, painting and assembly. Below you can get acquainted with the main developed products within the framework of the T-250 project:

Testing and measuring laboratory

June 23, 2015 became a particularly important date in the history of development of LLC "Uz-Koram Ko". It was on this date that the accredited testing laboratory of LLC "Uz-Koram Ko" was launched in accordance with the requirements of ISO / IEK 17025. Our testing laboratory is equipped with the most modern equipment of European manufacture. The laboratory accreditation area includes testing of unpainted and dyed plastic parts according to ISO, SAE, ASTM, GMW, EDS and a number of other standards. In turn, LLC "Uz-Koram Ko" is pleased to offer its services in testing plastic parts of the automotive industry and in other industries and also consider the possibilities of cooperation with our company in the field of laboratory tests

Project WLFT

According to the Decree of the President of the Republic of Uzbekistan No. PP-2264 dated November 17, 2014, on the investment program for the development of the enterprise in the fourth quarter of 2015, it is planned to purchase a new production line for the production of automotive parts from similar raw materials "WLFT (glass fiber)" and LLC "Uz- Koram Ko "plans to launch this production with the development of the details of the FRONT IMPACT BEAM model Gentra (J200 MCE). And also the issue of the development of parts for the seats of Gentra vehicles such as, for example, FRAME AF / CUSH, LH / RH, FRAME AR / BACK, LH / RH of which can be produced from similar raw materials by WLFT and LLC Uz -Koram Ko "plans to launch this production with the mastery of these parts.

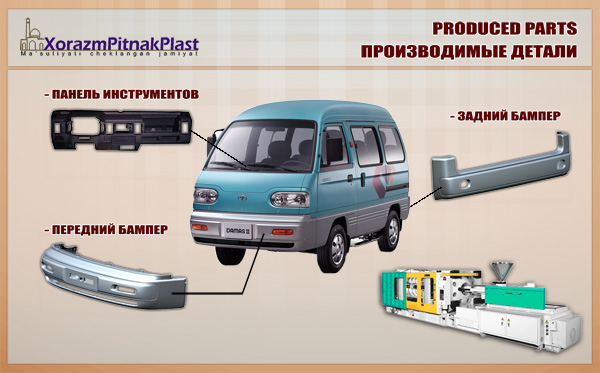

Khoresm

In pursuance of the Resolution of the President of the Republic of Uzbekistan No. PP-1856 of 22 November 2012 "On the Program for the Development of the Industrial Potential of the Khorezm Region for 2013-2015", the "Production of front, rear bumpers and instrument panels" was included in the investment project in LLC "Xorazm Pitnak Plast" ". In this regard, in April 2013, the construction of LLC Xorazm Pitnak Plast began in the production of front, rear bumpers and instrument panels of the Damas (B-150) model and by January 2014 the enterprise started its activities. In order to develop the Damas (V-150) model, Xorazm Pitnak Plast LLC was equipped with the equipment of injection molding machines with a clamping force of 2500 tons. together with ancillary equipment.

Production department №2

Within the framework of the investment project, by the Decree of the President of the Republic of Uzbekistan No. PP-1668 dated 27.12.2011 in 2012, construction of a new complex for the production and painting of small parts for the models Gentra, Spark and Cobalt on the basis of KOF-2 began. The first stage of production was launched in November 2012, when LLC "Uz-Koram Ko." Mastered the production of component parts for the "Cobalt" model. In May 2013 Production of component parts for the "Gentra" model began. In February 2014, an assembly shop was created and direct supply was introduced to CJSC "Jiem Uzbekistan". In April 2014, it was expanded due to the commissioning of 3 additional injection molding machines.